JJ White Successfully Completes Storage Tank Project Utilizing Alternate Construction Method for Midwest Client

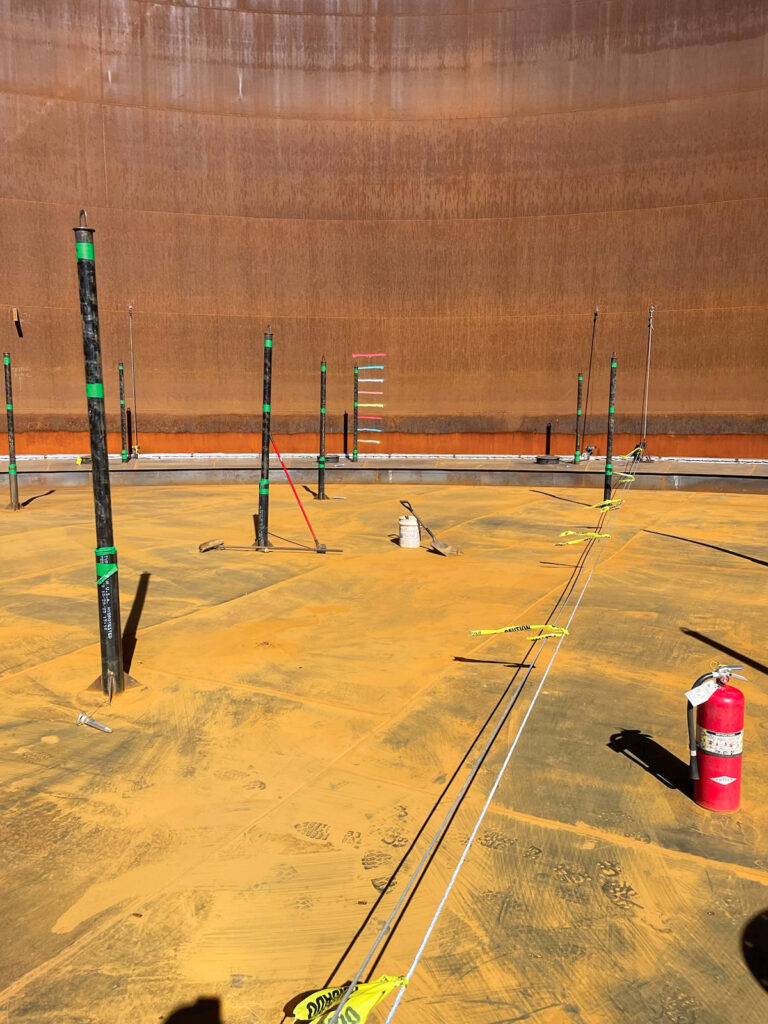

In the realm of industrial construction, efficiency and innovation often go hand in hand. JJ White recently underscored this principle with our completion of a project for a valued client in the Midwest. The highlight of the project was the installation of a new 128-foot diameter External Floating Roof (EFR), accomplished with an alternate technique that significantly improved project safety and schedule.

Air Raising Technology

Central to JJ White’s achievement was the use of Air Raising Technology for the floating roof. This innovative approach allowed us to lift the roof from floor level to its operational high leg position in under an hour, a feat that significantly streamlined the construction timeline. Unlike traditional methods that involve complex scaffold setups, extensive cleaning, and excessive water demand, air raising eliminated the need for those items prior to hydro testing. This not only saved valuable time but also reduced costs and simplified logistics.

Advantages of Air Raising Technology

Advantages of Air Raising Technology

The decision to employ Air Raising Technology provided several distinct advantages:

- Safety and Accessibility: By erecting the EFR at ground level, JJ White avoided the need for extensive fall prevention measures typically associated with elevated constructions. Furthermore, by nature of the air raise, the double tier doorsheet did not need to be fully welded out prior to raising. This allowed for its removal and for the space inside the tank to remain classified as non-confined.

- Environmental Impact: The construction process generated less waste compared to traditional methods, aligning with sustainable construction practices and minimizing the project’s ecological footprint.

- Efficiency: Rapid deployment of the floating roof facilitated quicker project completion, ensuring minimal disruption to ongoing operations at the client’s facility.

- Cost Effectiveness: Reductions in labor hours, equipment requirements, and material waste contributed to overall cost savings for the client.

Project Details

The scope of work involved not just the installation of the EFR but also ensuring the integrity of the existing tank bottom post-erection. Remarkably, no repairs were necessary after the roof was installed, highlighting the precision and meticulous planning involved in JJ White’s execution.

Client Satisfaction and Industry Impact

The successful completion of this project underscores JJ White’s commitment to innovation and client satisfaction. By leveraging advanced construction techniques and prioritizing safety and efficiency, JJ White has not only met but exceeded industry standards.

Moving forward, projects like these set a benchmark for future tank construction endeavors, promising greater efficiency, reduced environmental impact, and enhanced safety protocols across the industry.