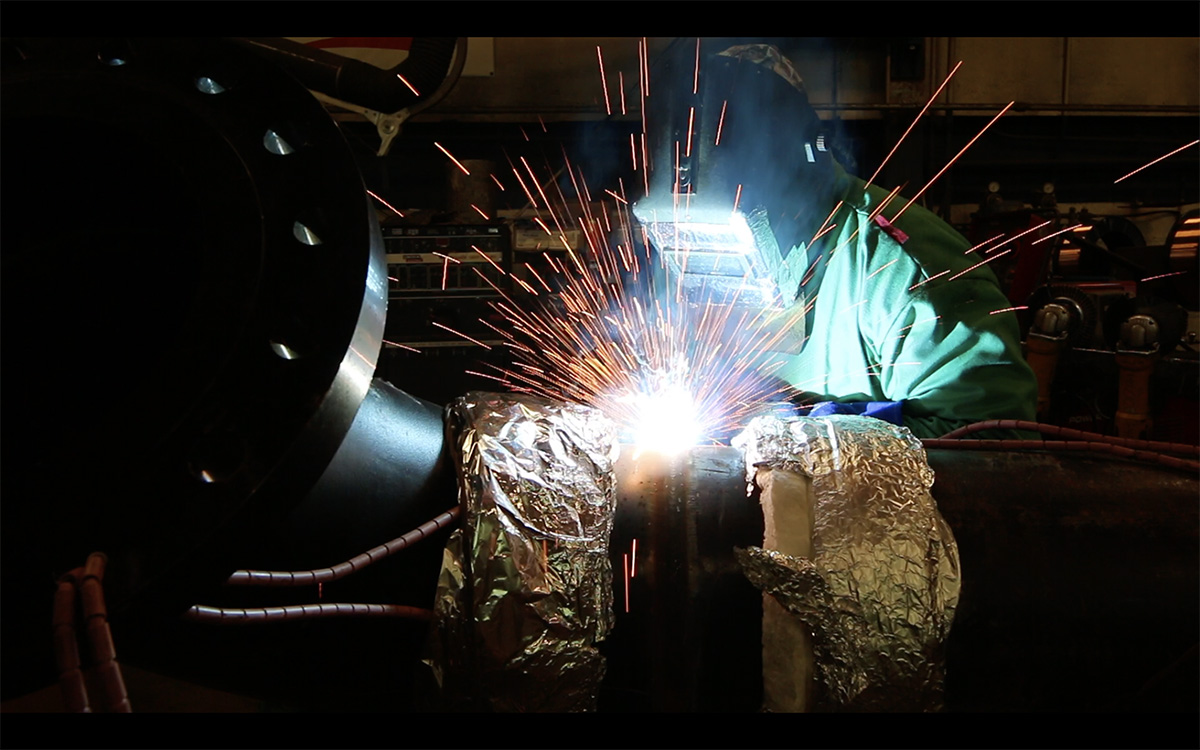

JJ White has an in-house Fabrication Shop capable of providing all of the custom fits for your project. The JJ White Fabrication Shop makes more than 100,000 Diameter Inches of Fabrication per year and is capable of up to 42 inch diameter piping.

"Thank you for the great job JJ White did on our 250 Manufacturing Building. Your crew was always professional, well skilled, and worked safely at all times. The finished work looks great. Thanks again."

– Richard L. McCormick | Vimco

I want you to know how pleased I was with the performance of your company. The level of service and commitment to the work was obvious to all of us here. I personally was responsible for the pipeline job and could not have been happier with the result. The support all through the planning stages of the turnaround was top notch. The cherry on top was managing to do all of this work without even a minor first aid case. Kudos to you and your company, I look forward to working with you in the future.

– Bill Devine | Sunoco Chemicals

I would like to take this occasion to thank you for your company's performance in outfitting our office space. I would like to thank you also for your personal attention to the progress of work on this job. I was always aware that you would respond personally to any concerns that arose. I am pleased to compliment all of the JJ White personnel who were assigned to work on our building. We expected that work on our building would reflect the outstanding skills of our local trades people and were not disappointed

– Jim Martin | Philadelphia Area Labor Management Committee

I wanted to convey that the technician you sent in was pleasant, professional, and knowledgeable. We talked initially and at intervals during the day updating and explaining issues and generally giving me understandable direction of his work. What a nice guy!

– Jim Leggoe | Borough of Lansdowne, Code Enforcement Department

I wanted to thank you for all your help this past summer. As you know, some of the jobs were difficult at best. With your help, and the help of your staff, we were able to pull it off without a problem. You also did a wonderful job keeping track of all the numbers and changes on the job and your organizational skills were invaluable. It was a pleasure working with you and I'm looking forward to future jobs together

– B. Kroh | Temple University, Department of Facilities Management