Situation

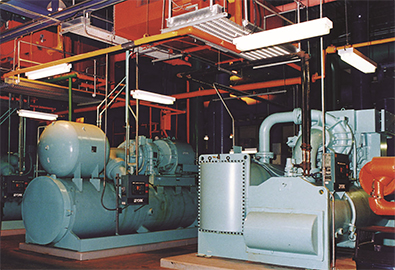

Chillers remove heat from liquid and are used in large-scale commercial, industrial, and institutional facilities. These giant machines can weigh multiple tons and have a life span between 15 and 25 years. When the time comes for replacement, JJ White’s HVAC has the experience, tools, and capability to replace chillers safely and efficiently. That is why pharmaceutical giants GSK and AstraZeneca both turned to JJ White Inc. for their chiller replacement jobs.

Challenges

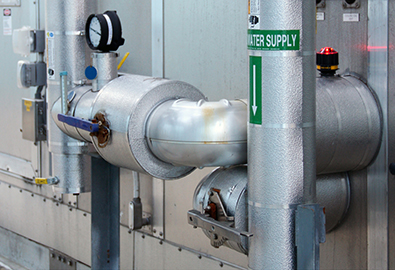

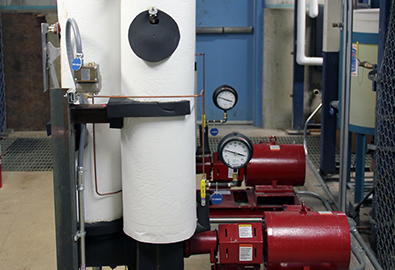

As with any chiller replacement job, access to the previously existing machinery is often a challenge. Mechanical rooms are often cramped and difficult to access by regular means. There are also various other systems connected to the chiller machinery such as chilled water and condenser water. Massive chillers also have long delivery dates that can set projects back by months.

Solutions

JJ White crews used their significant experience with and knowledge of chiller replacement projects to successfully work around all of these challenges at both jobs. Alternative access points through roofs and other access points were utilized to decommission and remove previously existing machinery. Specialized tools from within the JJ White HVAC team were also used to safely uninstall and remove these items. Project superintendents worked with owners at each site to shut down systems that are tied into the chiller. JJ White also created individualized project calendars to mitigate the effects of extensive delivery wait times.

Results

Both the GlaxoSmithKline and AstraZeneca facilities now have fully programmed, balanced, and tuned chiller systems. JJ White crews were able to complete the job on-time and under-budget, allowing both companies to advance their pharmaceutical goals and keep employees happy.