Details

- 4 man Crew: 1 – SF GF / 2 – SFW / 1 – SF

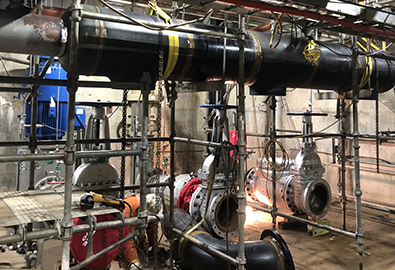

- Original Scope was to replace all piping from the block valves at the pumps up to the 2nd floor making the final tie in at the existing 24” elbow

- Original Work Schedule was 6 weeks with a 6 x 10 schedule. The client requested us to modify the work scope to 5 weeks on a 5 x 10 schedule

- All work was completed on time according to the client’s new schedule without any incidents.

- Original Planned Man Hours: 1935

- Project Completion Man Hours: 1010

Challenges & Barriers

- Low head room to hang proper rigging. Brand Scaffolding was able to build scaffolding rated for rigging to assist with varies points to hang chain blocks.

- Removing old piping from the basement and 1st floor using the Gantry Crane to lift through the designated shaft to the outside hard deck.

- Lowering new piping from the outside hard deck into the basement and 1st floor using the Gantry Crane.

- All was done successfully without incident.

Work Completed

- Demo all old piping and valves along with disposal.

- Fabricated all new piping on site and install.

- Welds:

- 14 – 24” welds

- 10 – 16” welds

- 1 – 12” weld

- 6 – 4” welds

- 5 – 6” welds

- Several miscellaneous small bore welds 2” and under

- Valves:

- 1 – 16” 150# Check Valve

- 1 – 16” 150# Gate Valve

- 1 – 24” 150# Gate Valve

- 1 – 6” 150# Gate Valve

- 1 – 4” 150# Gate Valve